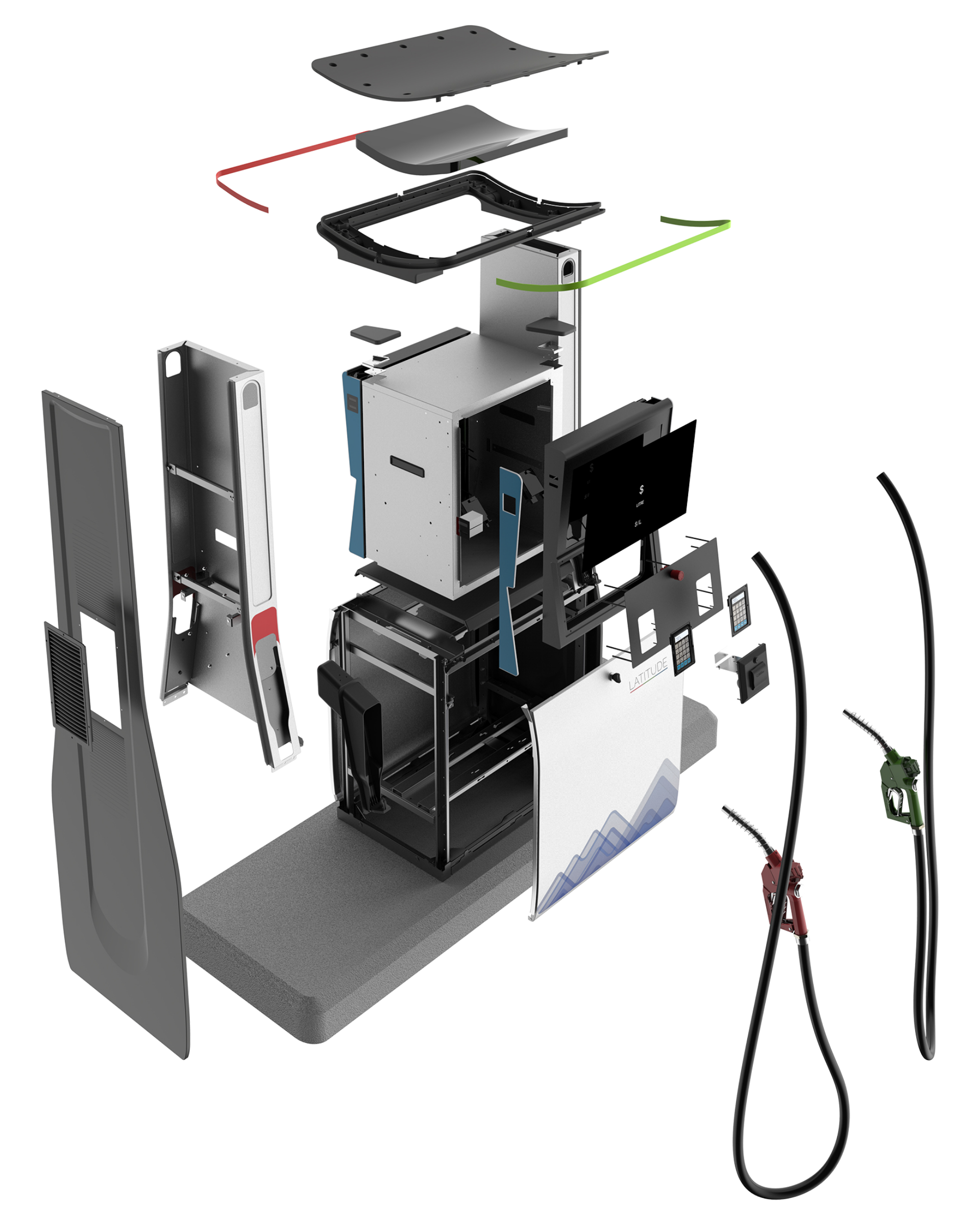

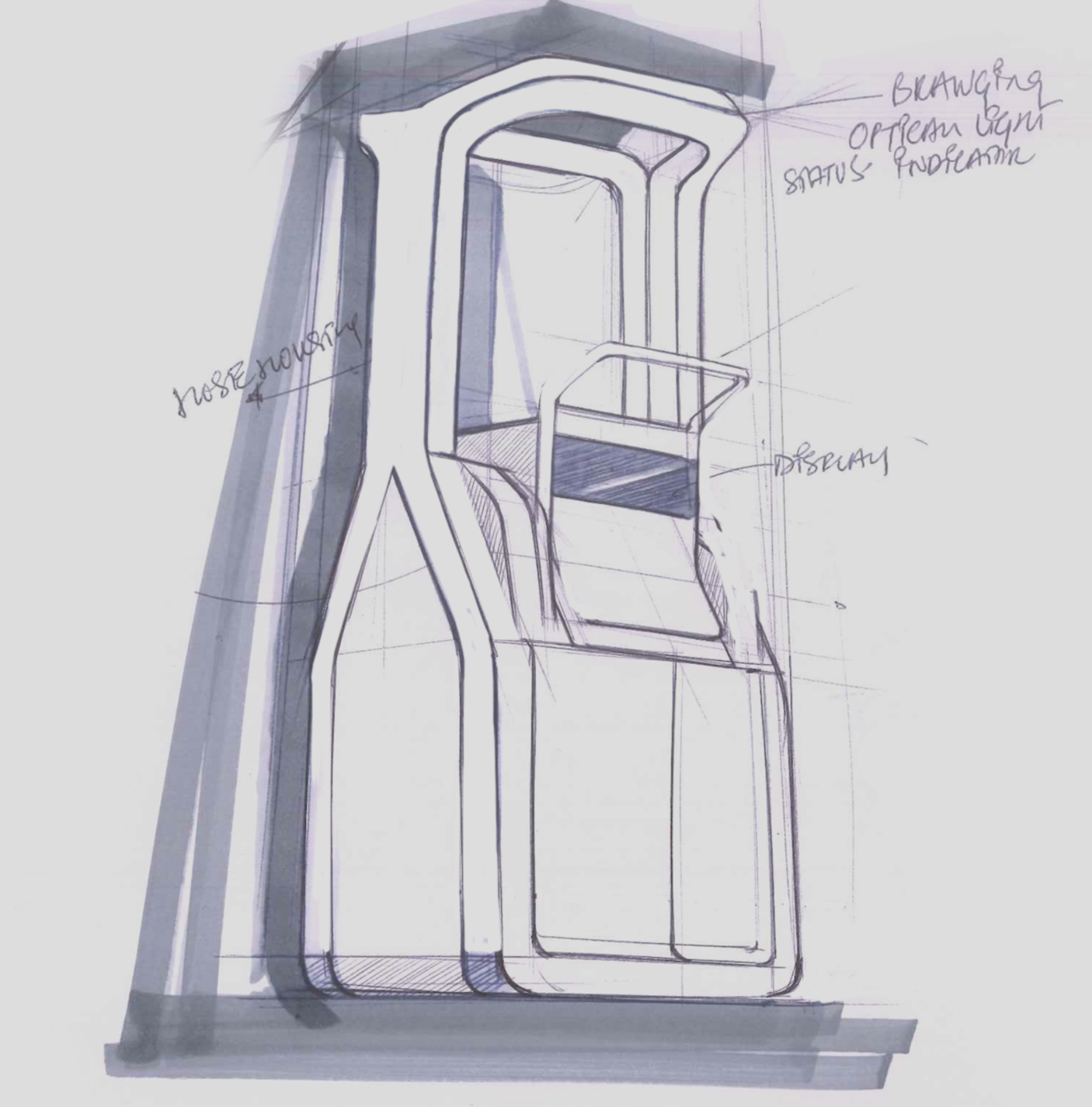

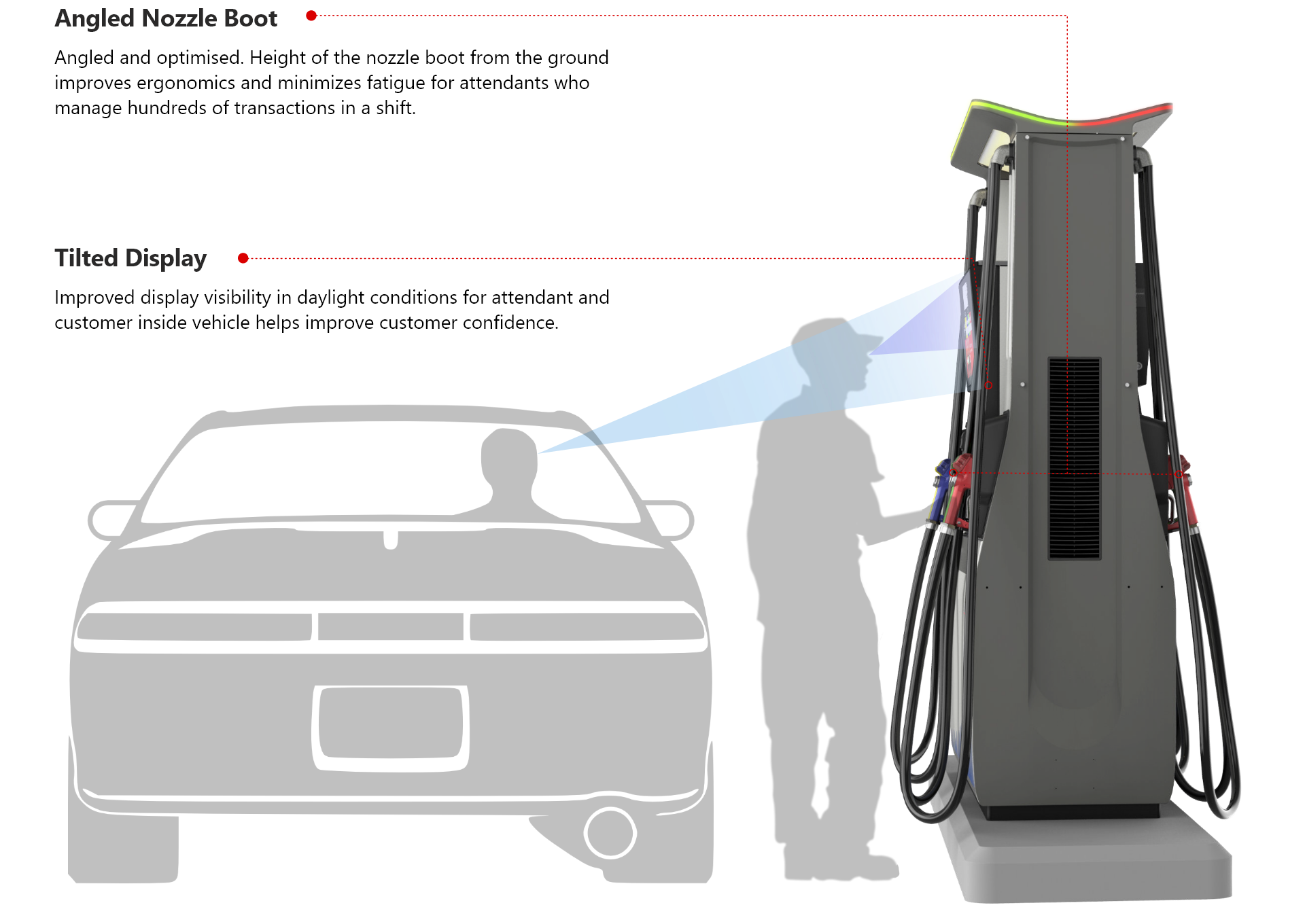

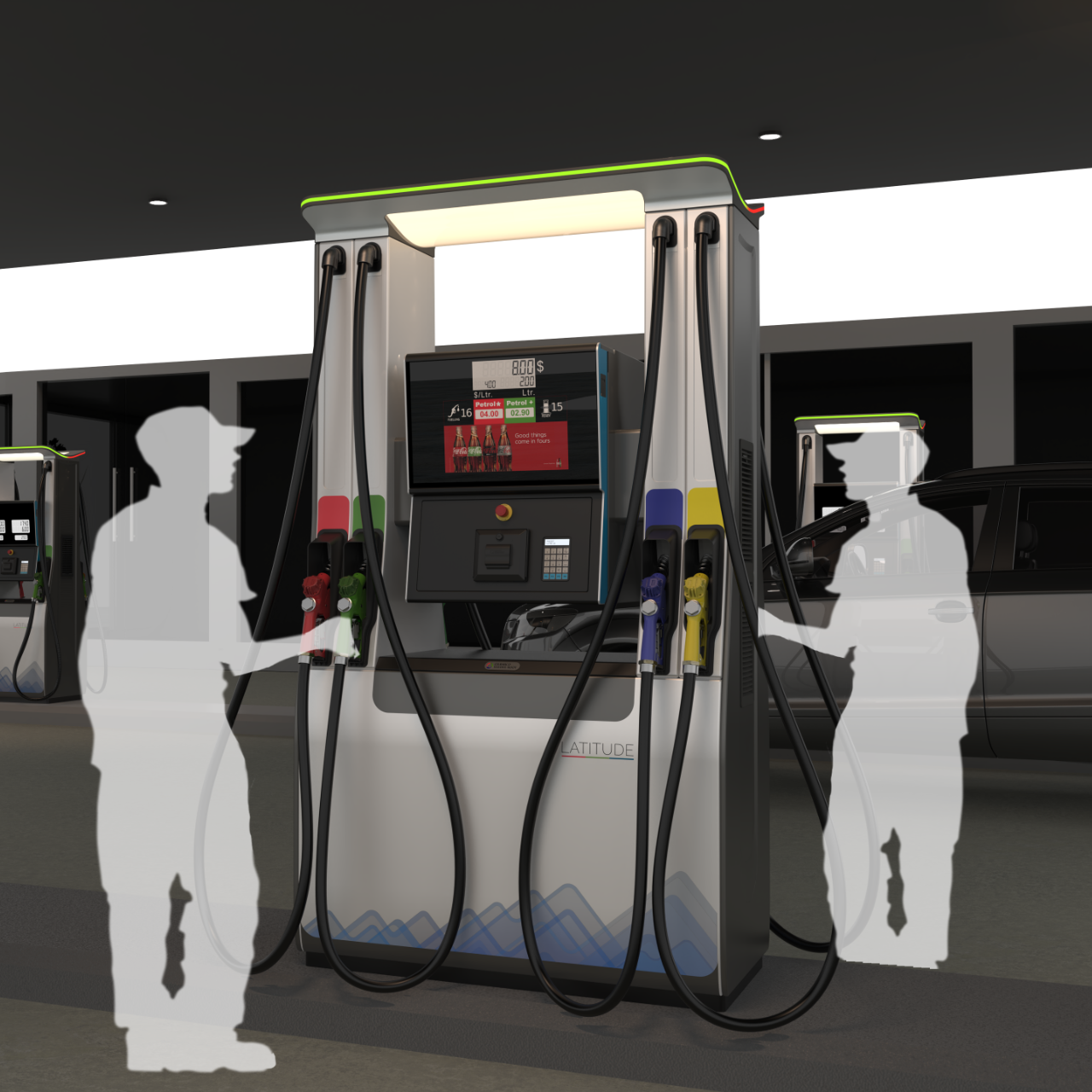

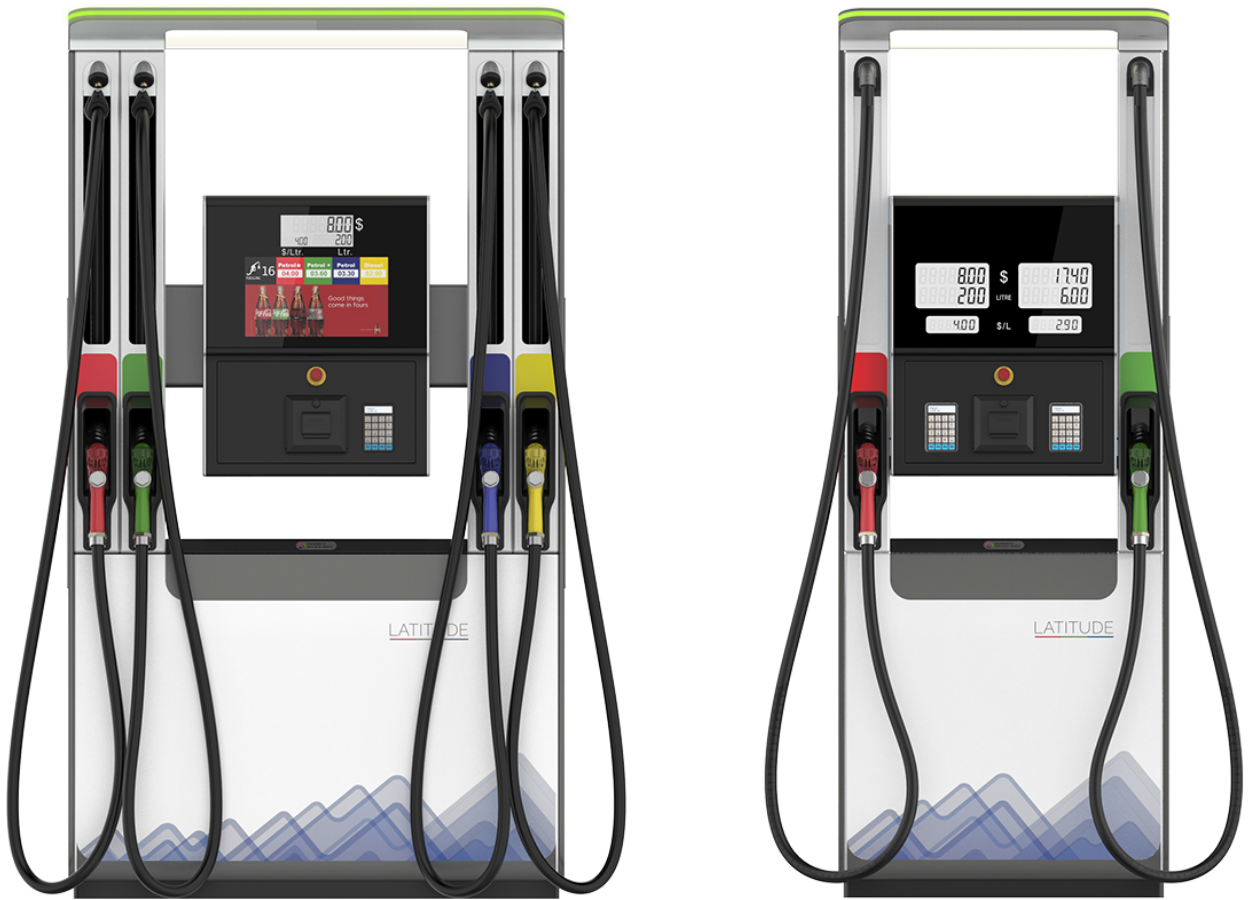

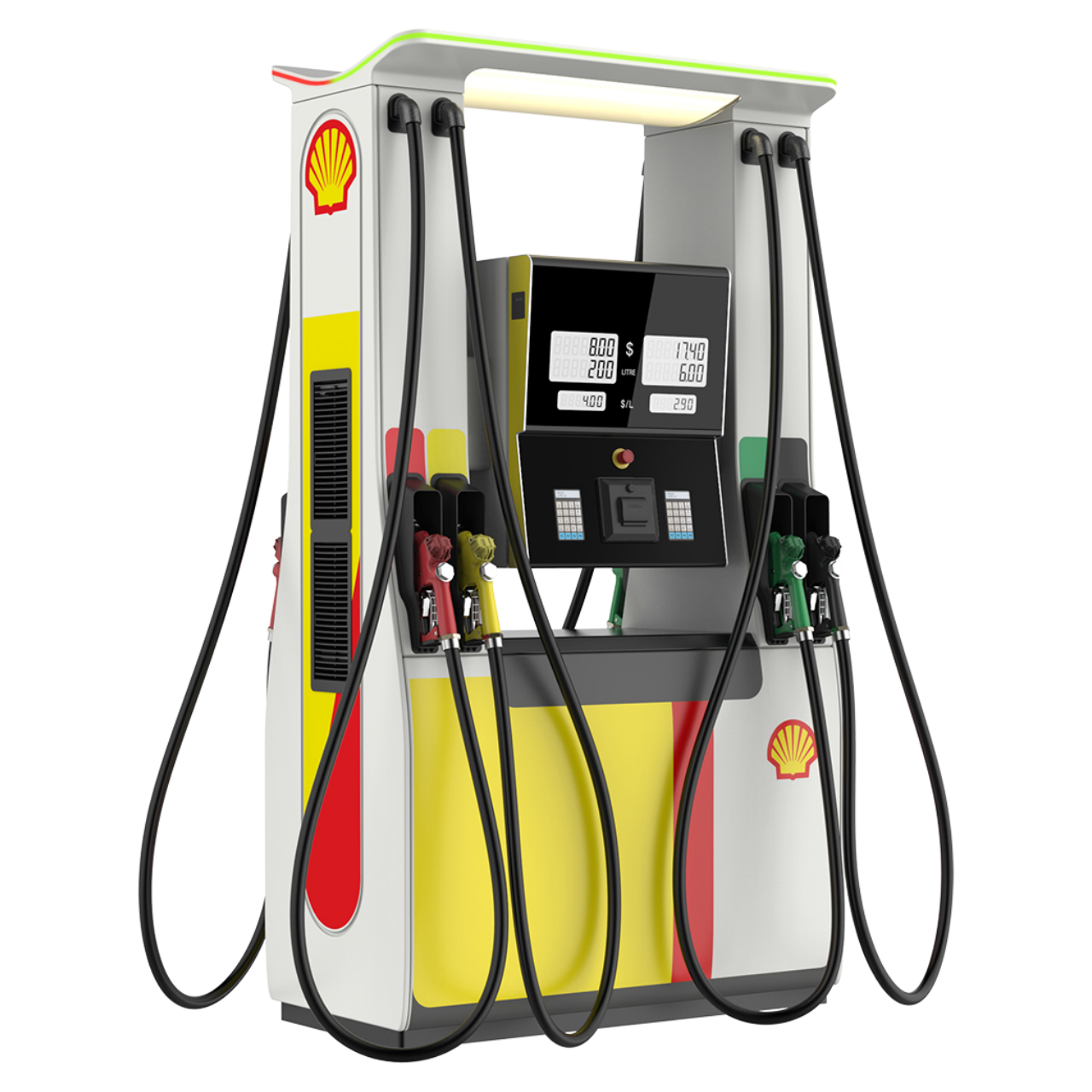

The crossfunctional team at Futuring and Gilbarco worked on design detailing with a goal of building a well designed product. The team focussed on structural design of large pressed metal parts, plastic components, lighting details and fit feel finish. This approch helped in ensuring seamless assemblies and a superior professional equipment which will ensure desired perfomance over the years.

The collaborative working ensured a superior aesthetics, well designed experiential product with many firsts in this sector.

A complete task analysis of the assembly process was imagined which allowed us to address issues and simplify them, making the assembly more efficient. During this design process, every attention was given to user experience, ergonomics, functionality, serviceability, manufacturing, logistics, guidelines and regulations.