impressions.

experiences.

brands.

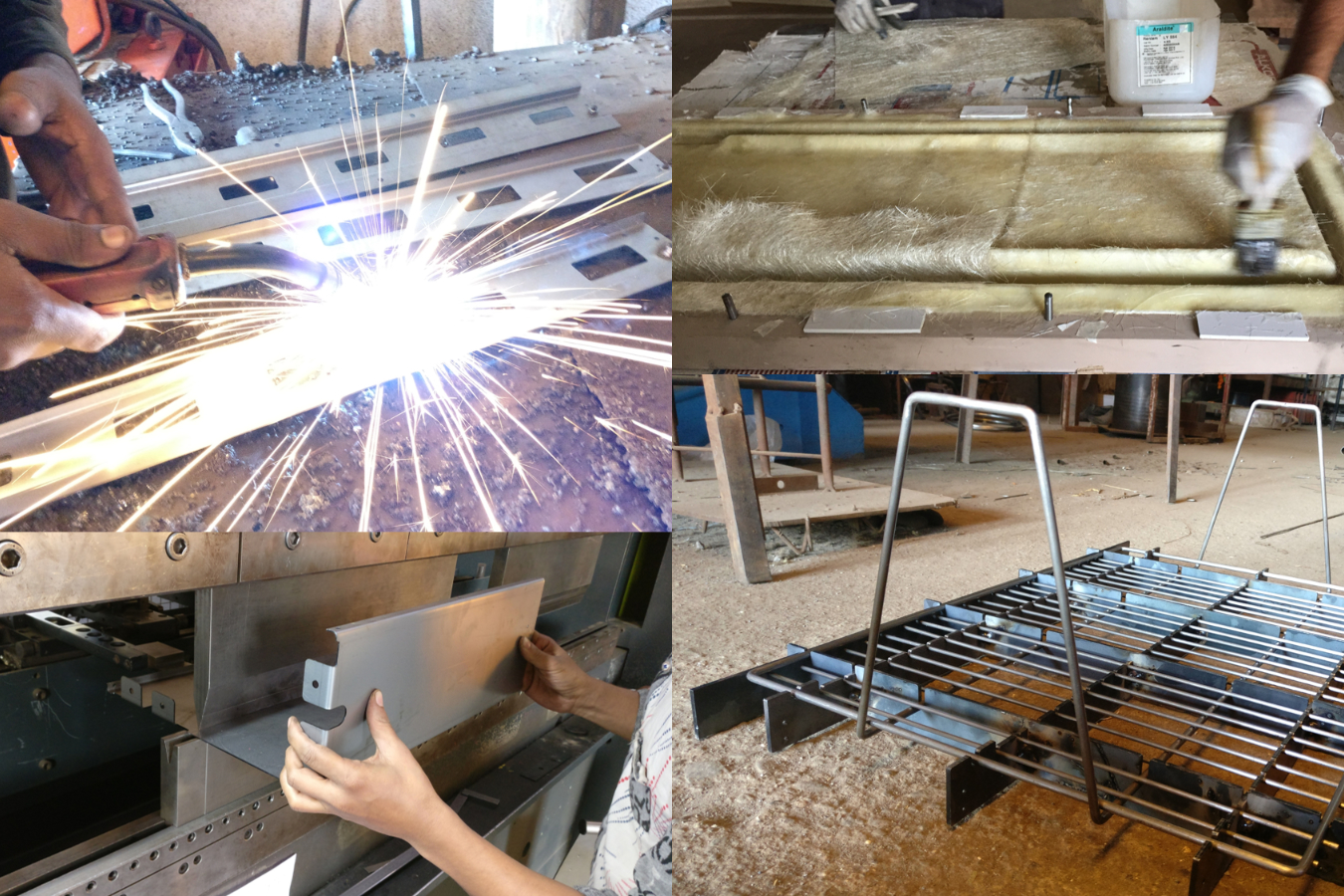

Futuring Design alongside our sister brand FOMO specializes in creating prototypes that bring concepts to life, facilitating visualization of product concepts, better communication between stakeholders and validation of design ideas. Since the models we make are lifelike, we are able to get valid user feedback. This helps us refine designs, making them more functional, user-friendly, and impactful.

We utilise an integrated approach to design known as ‘Design 360’. This comprehensive product development process encompasses Design Research, Design Conceptualization, Product Engineering, and Design Prototyping. Prototyping is a critical part of our strategy for product innovation because we can iron out many kinks in the design before its mass manufacture.

Developing prototypes that accurately represent design ideas requires a diverse skill set. Our team includes some of the best engineers, designers and skilled model makers who combine their technical expertise and creativity to deliver best prototypes.

A typical design prototyping project follows these phases within our Design 360 approach:

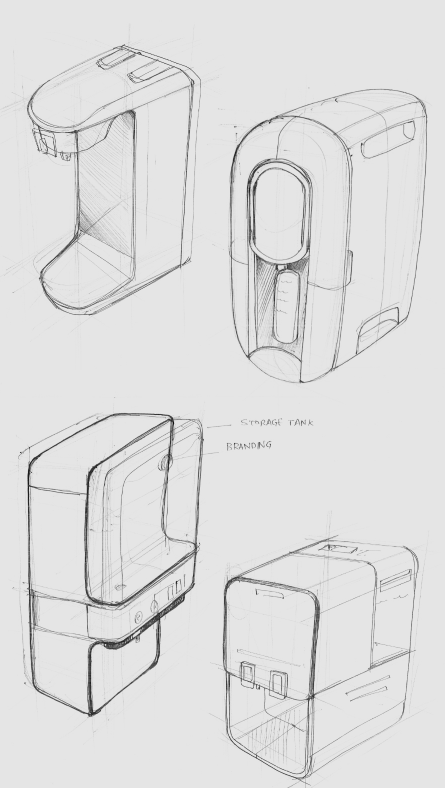

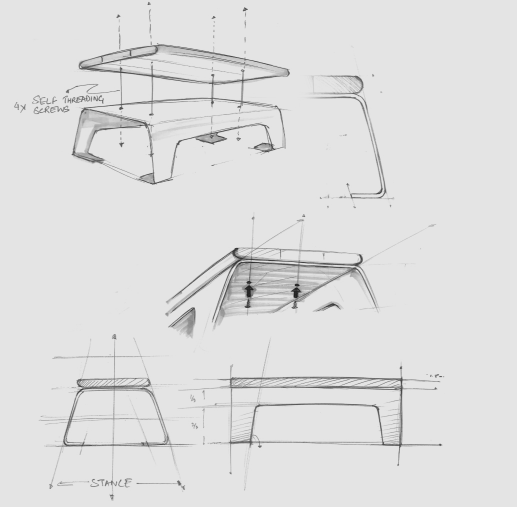

In this stage, we can use Proof of Concept (POC) models or form studies done with foam to receive feedback on aesthetics and ergonomics. This helps decide the design direction.

At this stage, we use rapid prototyping or even paper prototyping to get feedback on design attributes.

Once the design concept is finalized, we create high-fidelity prototypes that accurately represent the final product. These prototypes are finished with lifelike colours and finishes to ensure authentic user feedback.

Our CMF designers and model makers create swatches of colour and finish options. Our engineers work with the client teams/ vendors to evaluate the feasibility and durability of the selected CMF concepts. We focus on ensuring that the chosen materials and finishes meet market and user needs and also fit technical specifications, sustainability goals, and manufacturing capabilities of the client.